Car Being Picked Up in the Middle of Dairy Farm Country in The North Island

This is something different. 2007 Aston Martin DB9 V12 6.0 Litre SuperCar.

It was imported into New Zealand in 2018 and the Motor Imploded on the way to compliance. Bet the apprentence who was driving it got a right telling off!

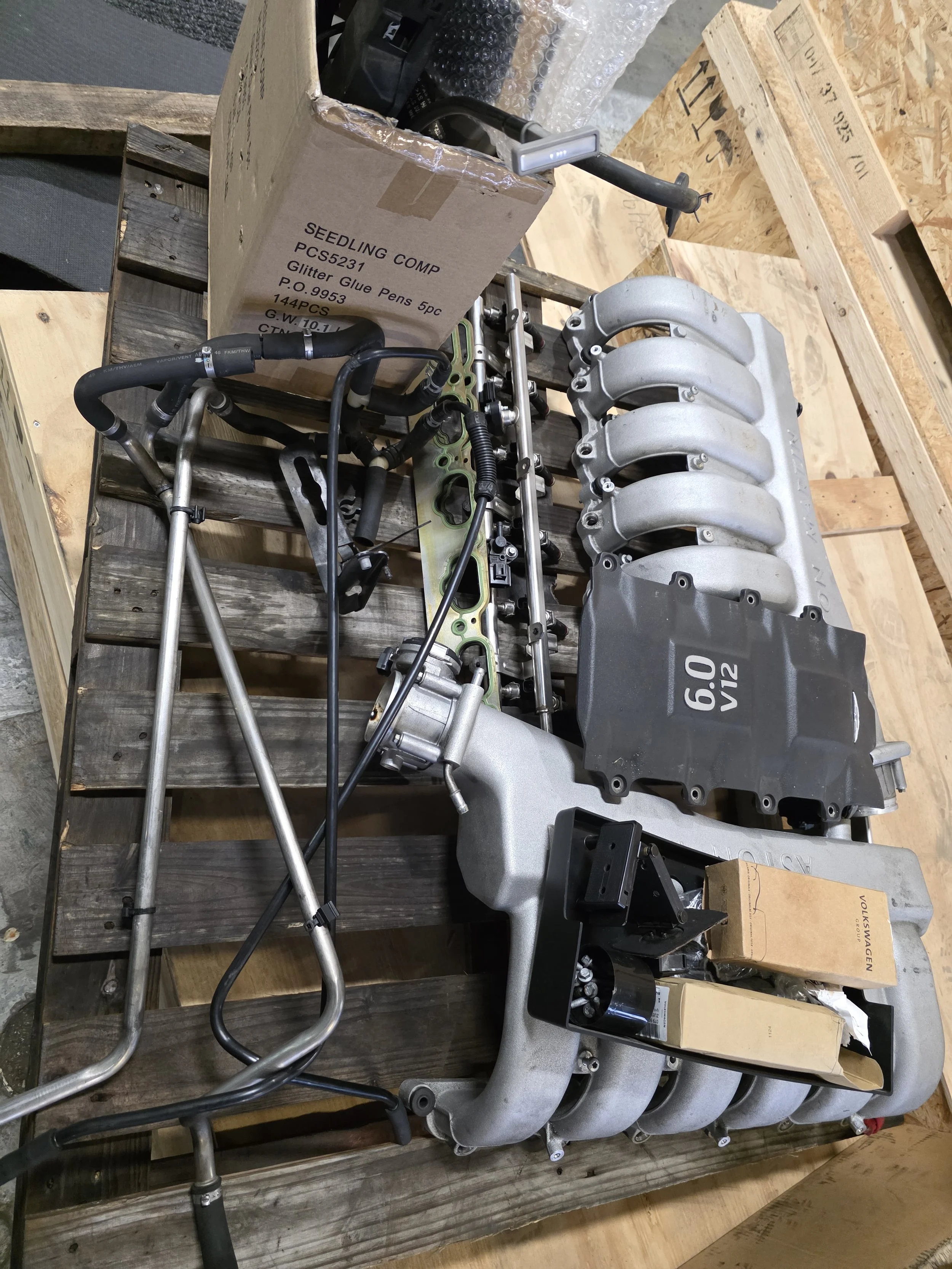

Anyway we ended up with it originally thinking of it being a great LS repower but suprise suprise we opened the boot and here were the missing Motor Parts.

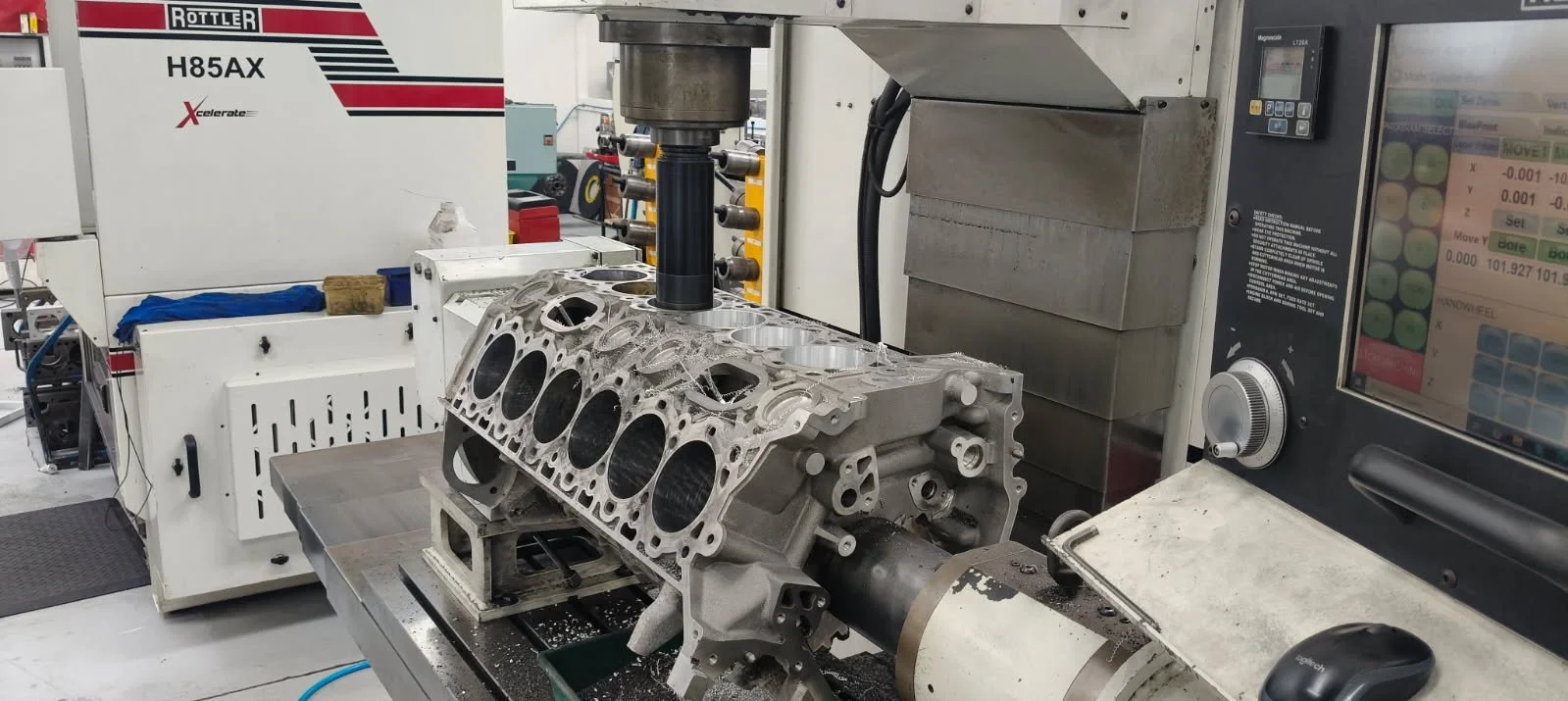

So the Block is being welded up as you can see in the photos.

There will be new liners put throughout the total block.

We have 4340 forged pistons and conrods being made and HPE will be doing the engine machining and block assembly.

Suprise!

The Original Engine Bits that were missing.

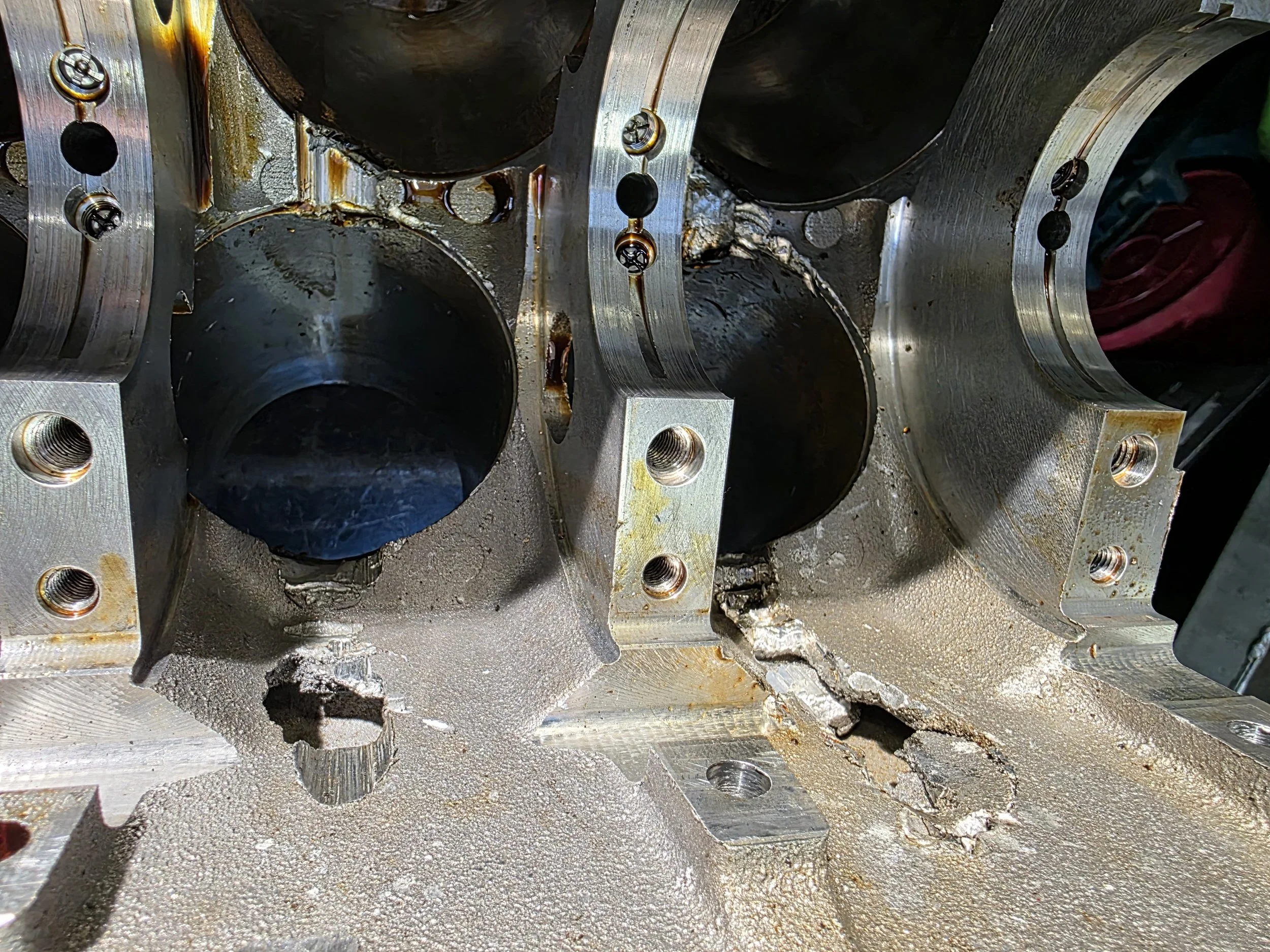

The External Damage to the Block. No waterways Damaged so easy repair.

External Crack repaired. Yet to be peened and tidied up. We have dye tested for pin holes and hair line cracks. No leaks so should be good.

Old Liners being removed

The Internal Damage to the Block. These are just Oil Drains from the Heads so not to bad really.

One hole welded up. We scanned the hole, loaded into Fusion 360 and scaled. Then cut the patch from 5083 6mm Aluminium and it fitted like a Jig Saw Bit and easy weled in. Yet to be cleaned up.

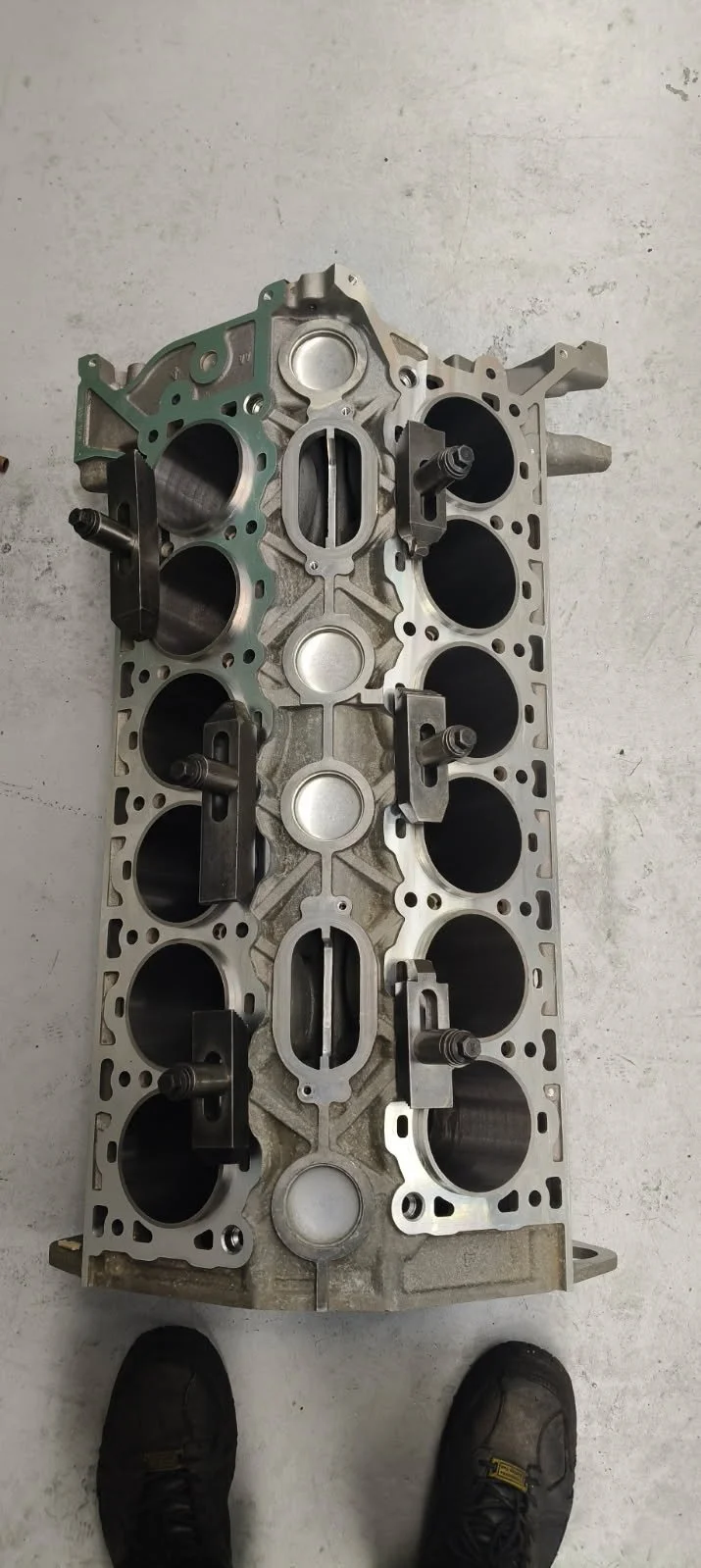

New Liners Installed

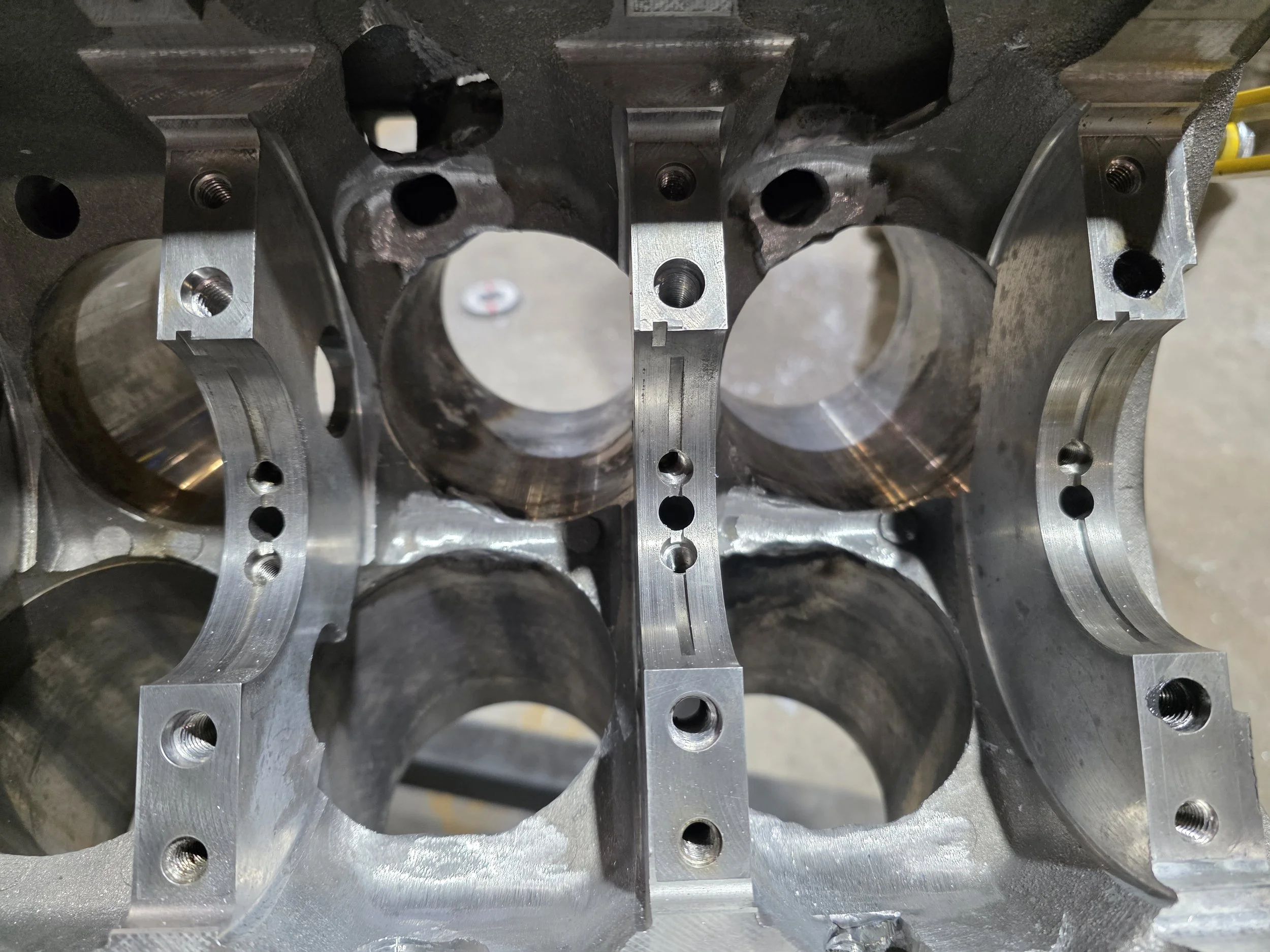

Bored , Decked , Chamfered ready for the forged pistons and rods to arrive!

The Engine at HPE for stripping down

A lot of Valves

Here is why it happened. The Germans in their infinite wisdom decided to put a chamfer on the bottom of the dry liner to make it easier for installation and this caused only a 1 mm landing for the liner to rest in the block. The rear 4 Cylinders dont cool as well as the front ones and here a liner has sunk, probably only 1 thou or 2 but enough for the hot cylinder gases to get between the dry liner and the block. You can see the carbon on the block wall once the liner was removed. The Liner heats up as its lost its cooling and grabs the piston, breaks the conrod and causes chaos. We will not be putting a chamfer on the new liners and will liquid nitrogen them to shrink before installation.

Slowly repairing the damage in the block. It is a beautiful to weld cast block of Aluminium. We used our Kempi AC/DC TIG with AliSheield (Argon and Helium Mix) to help wet the welds in nicely. Block was warmed up in front of the workshop heater to a warm to touch temperature.